This post is part of a set of posts following my project to "E" my Brompton :

A. Wheel Building - Tongxin in Brompton wheel

B. Building a small A123 Battery Pack

C. E-Brompton First Ride/Tweaks

D. Taking a Tongxin motor apart

You may also like to check out daniel.weck's post here which covers the simlar use of Tongxin & Bafang motors and inpired me to give this a go.

A couple of related links as I was building

Throttle Controls

Connectors

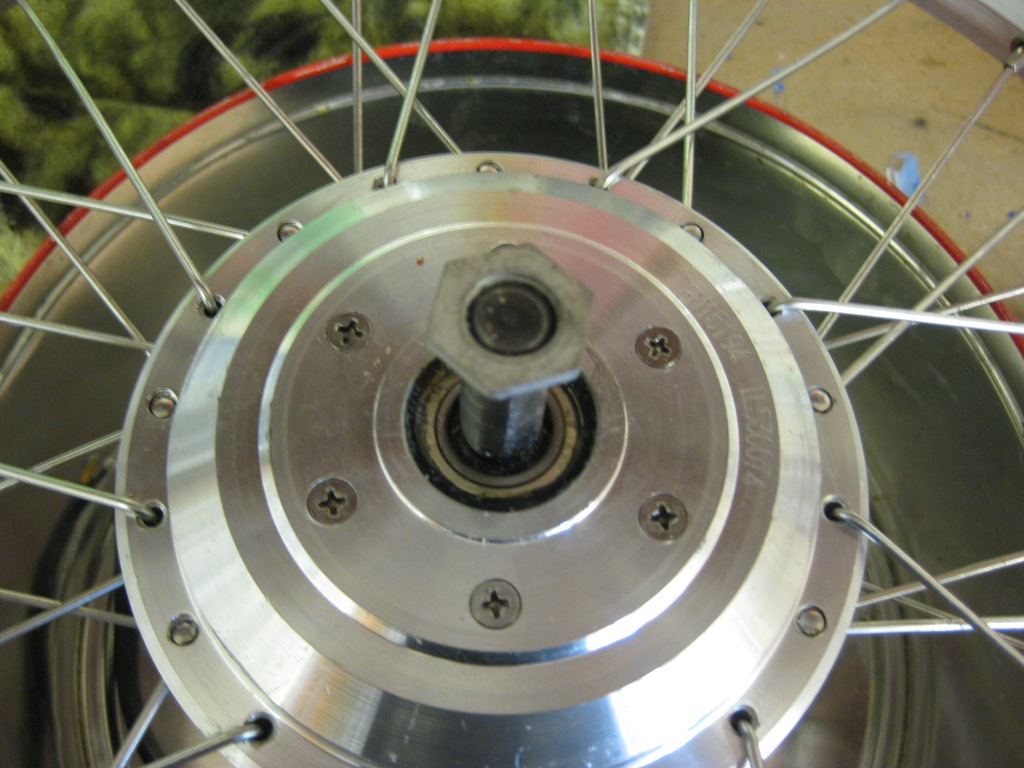

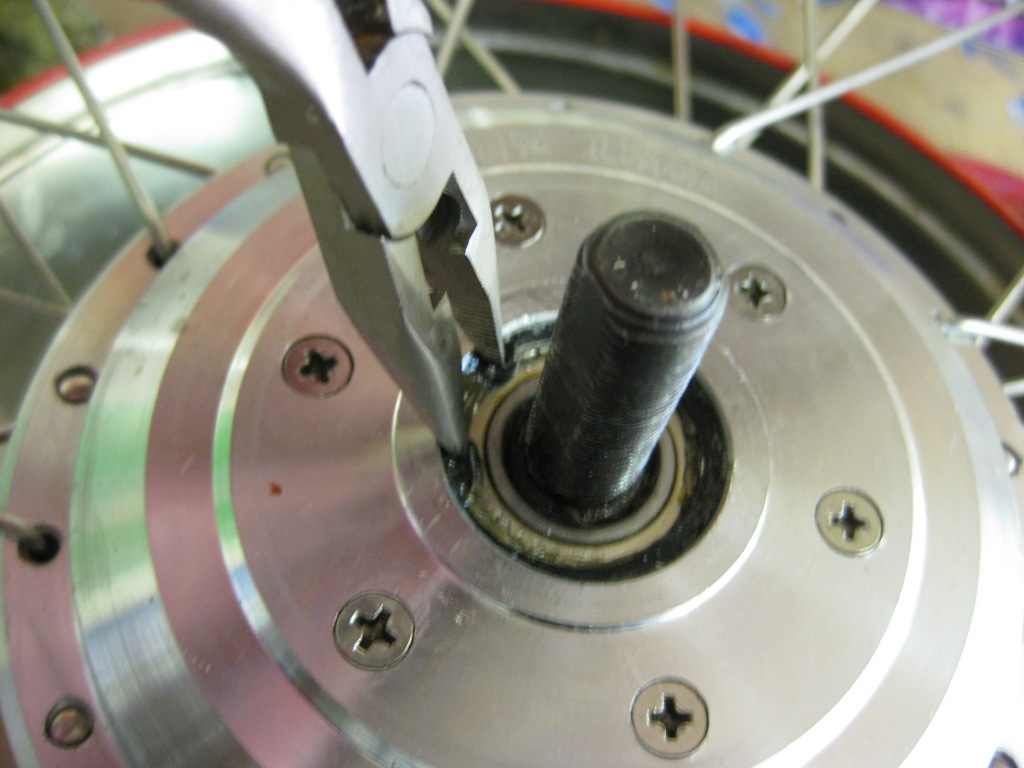

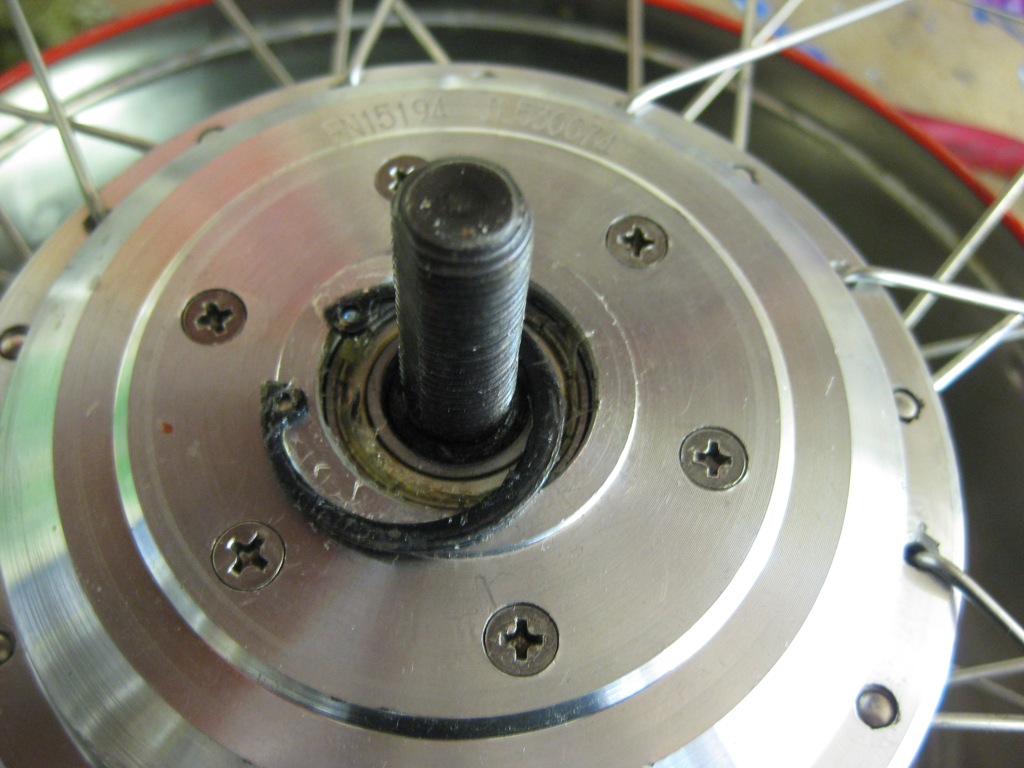

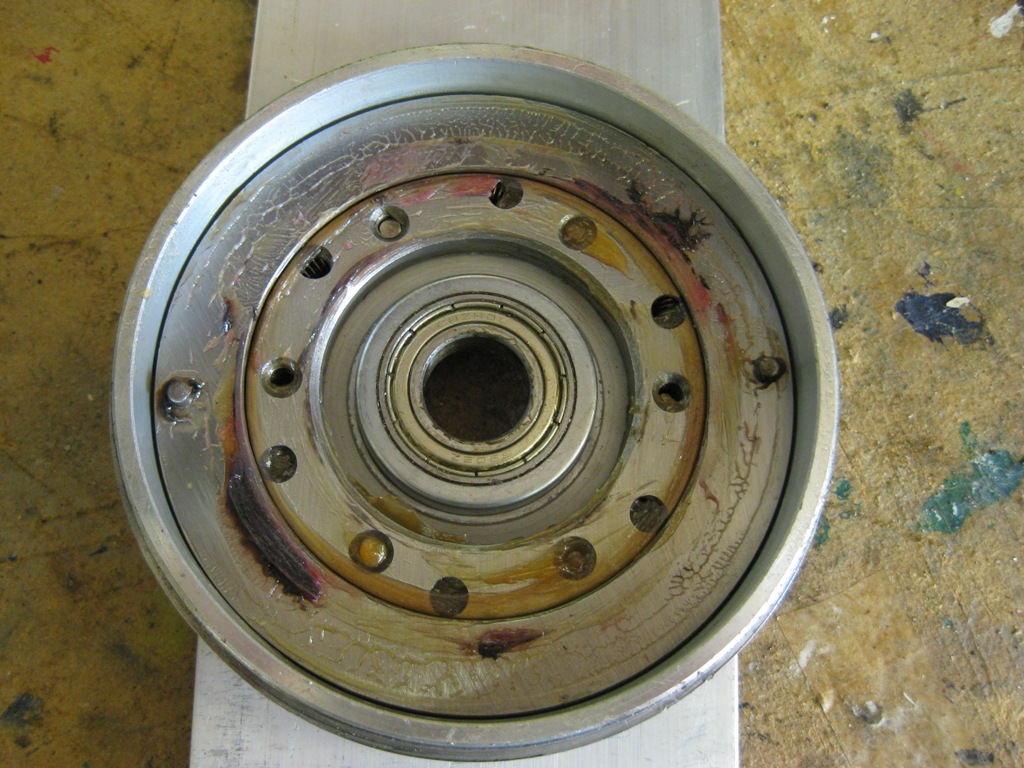

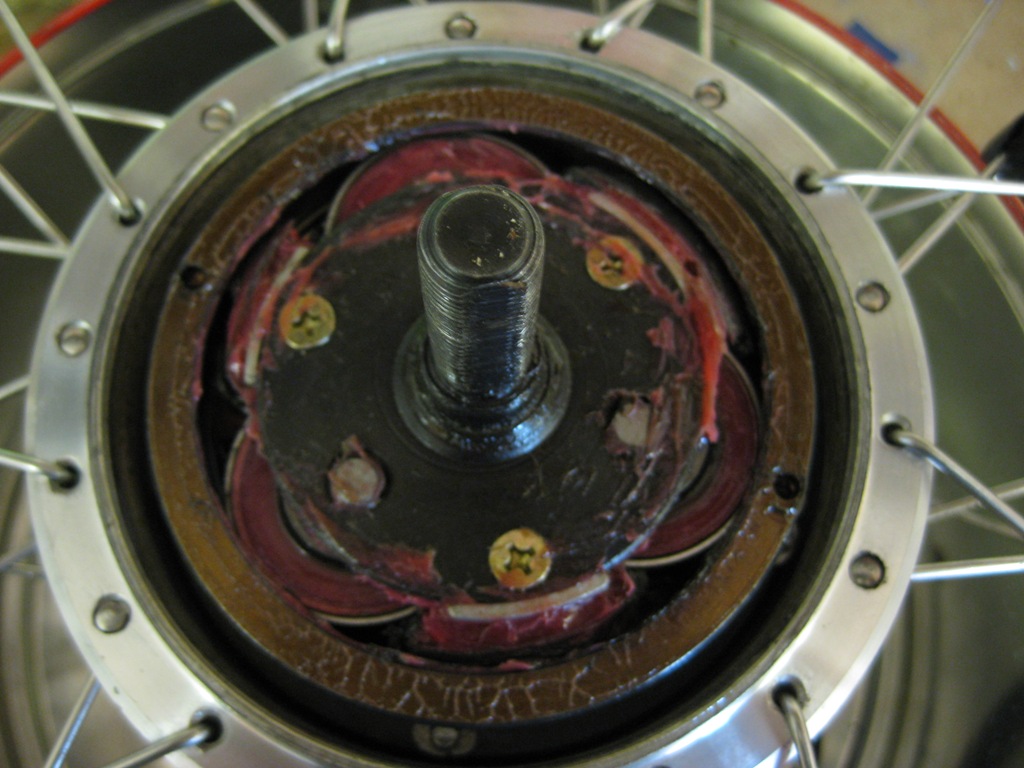

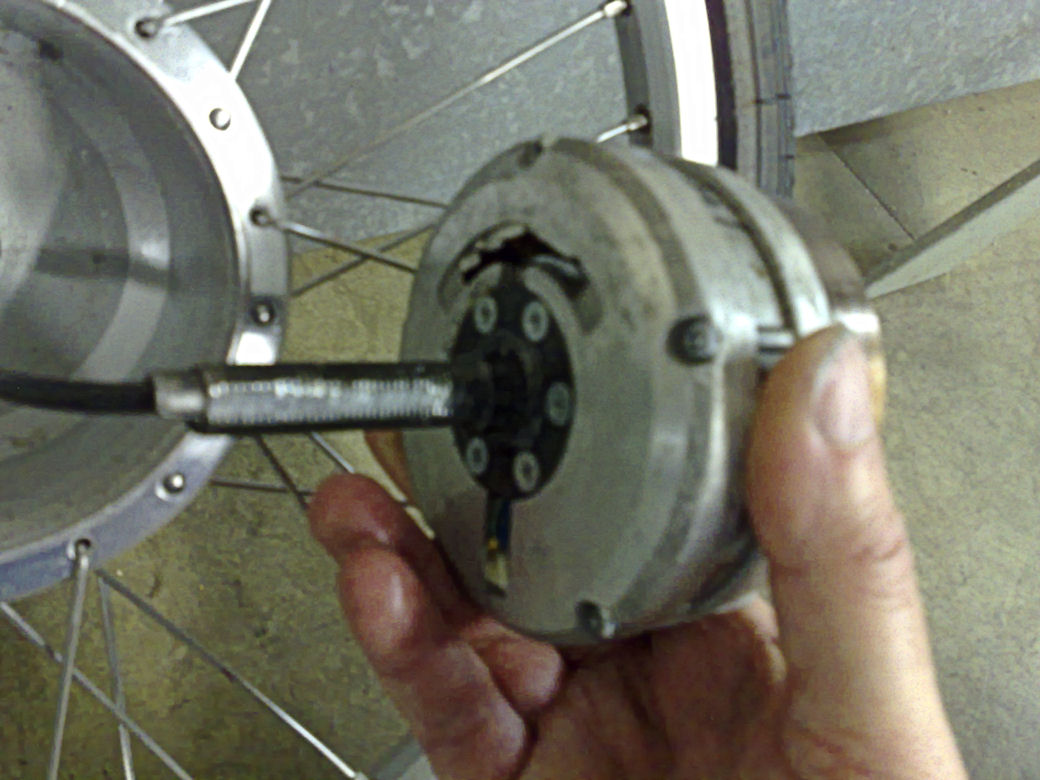

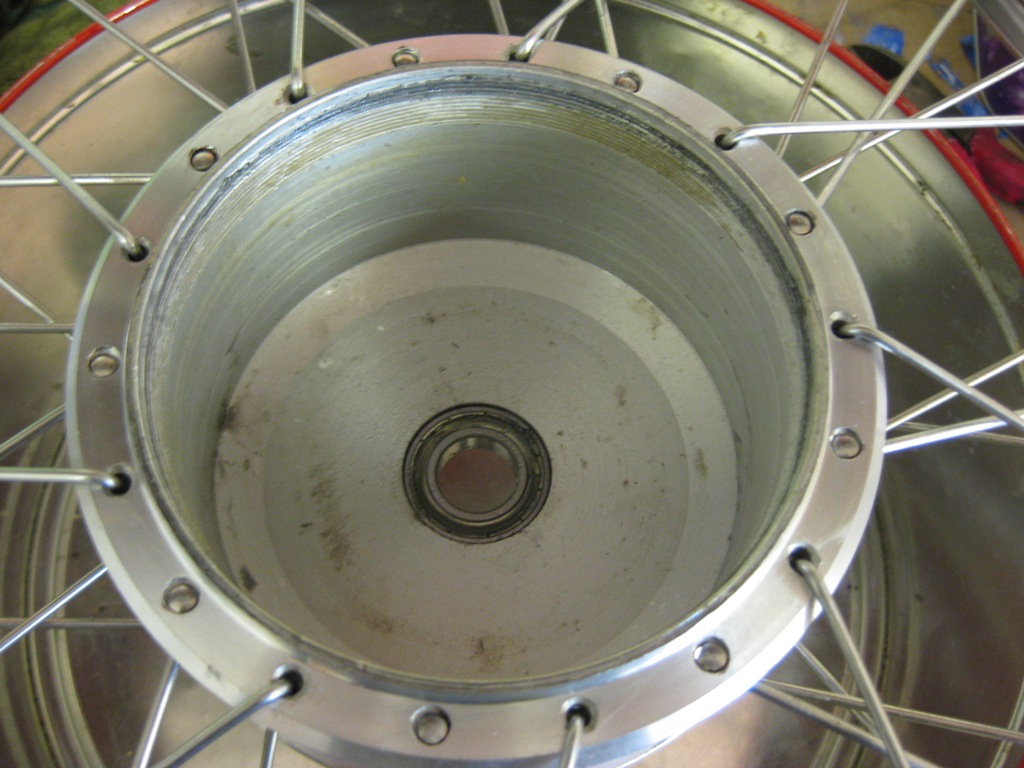

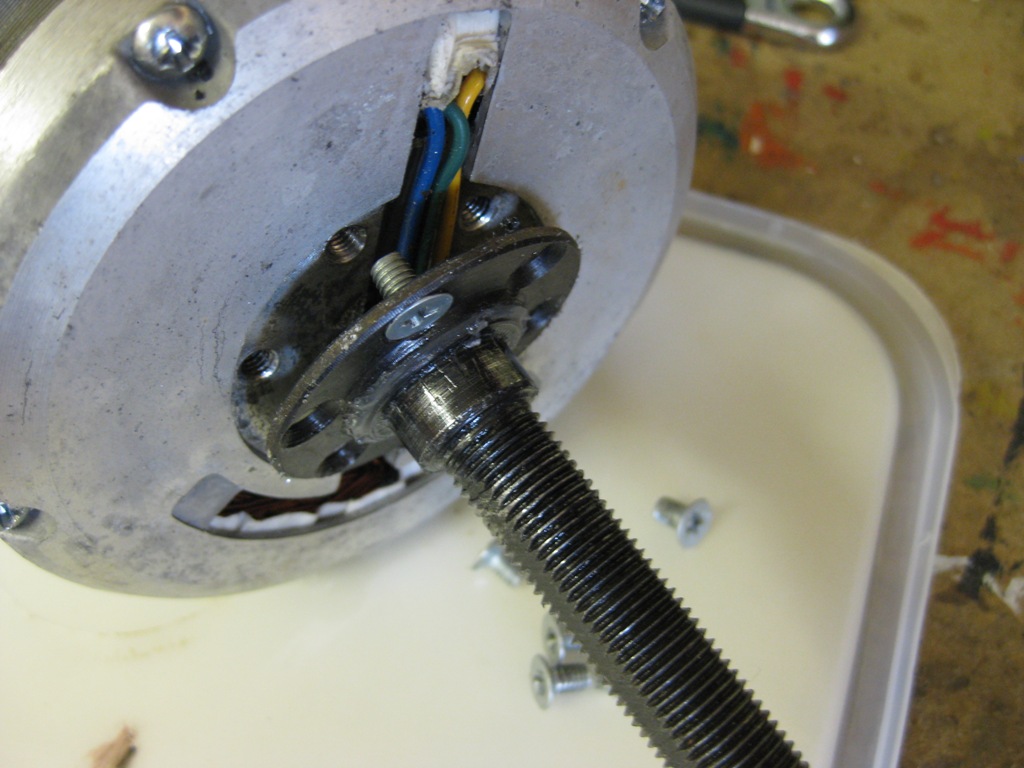

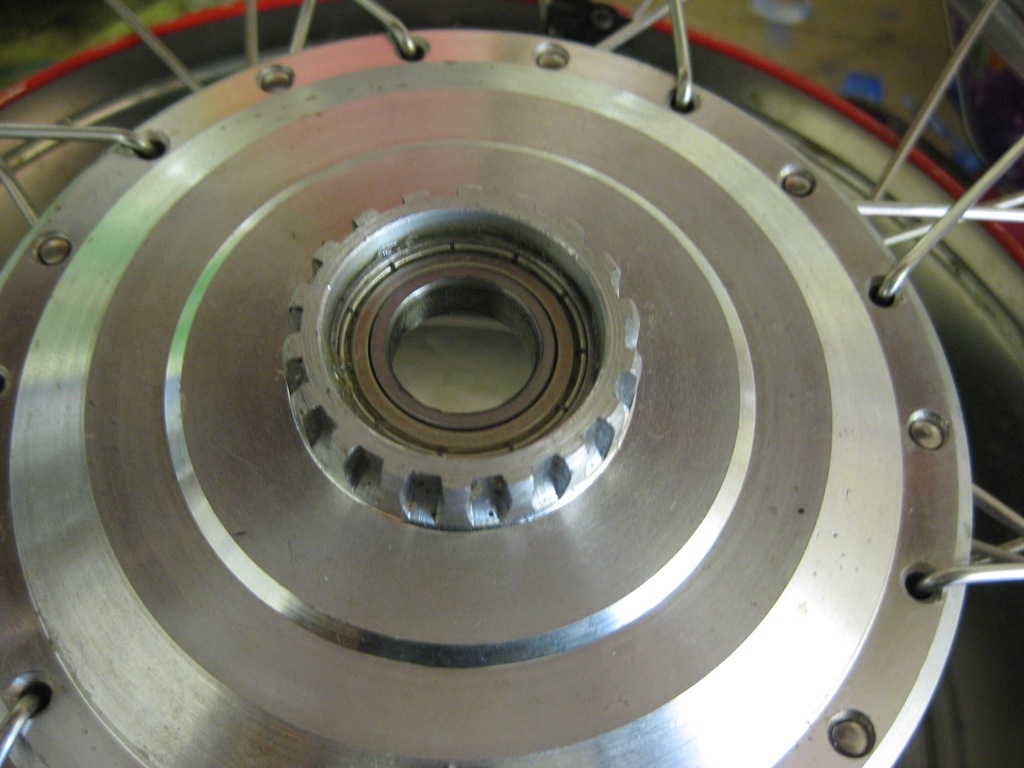

After about three month I had problems with my Tongxin motor and intially stripped it down as shown in this post. I took the motor apart using a vice to clamp the motor plate but this is not really advised as you can easily strip the threads. The other thread also had some pretty blurred pics. I have therefore posted this breakdown as there seems to be very little on the internet about taking these things apart or any decent pictures. I hope it will be of use to some in the future.

I also want to say a big thanks to the member "mkc1" who helped me get to this point.

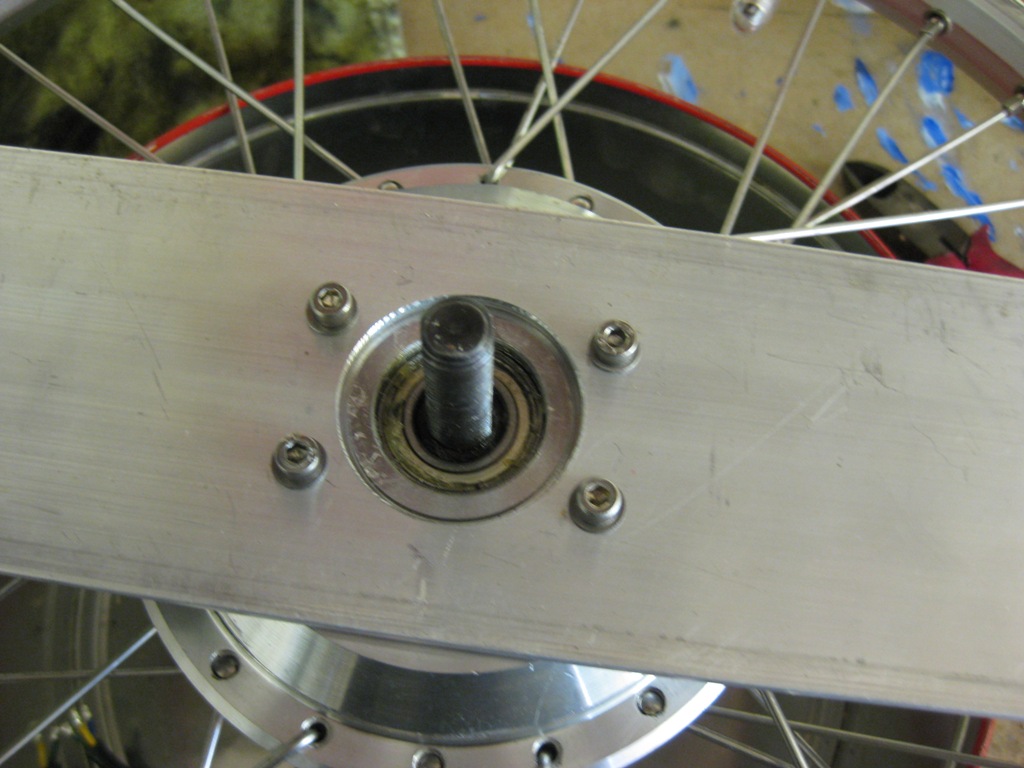

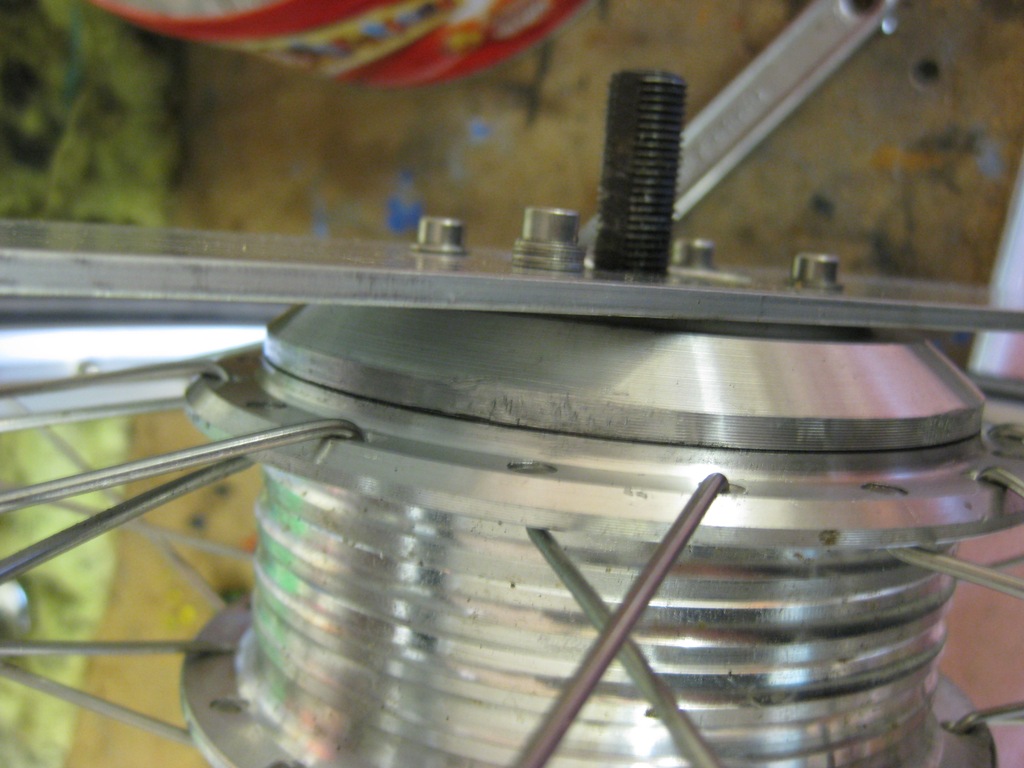

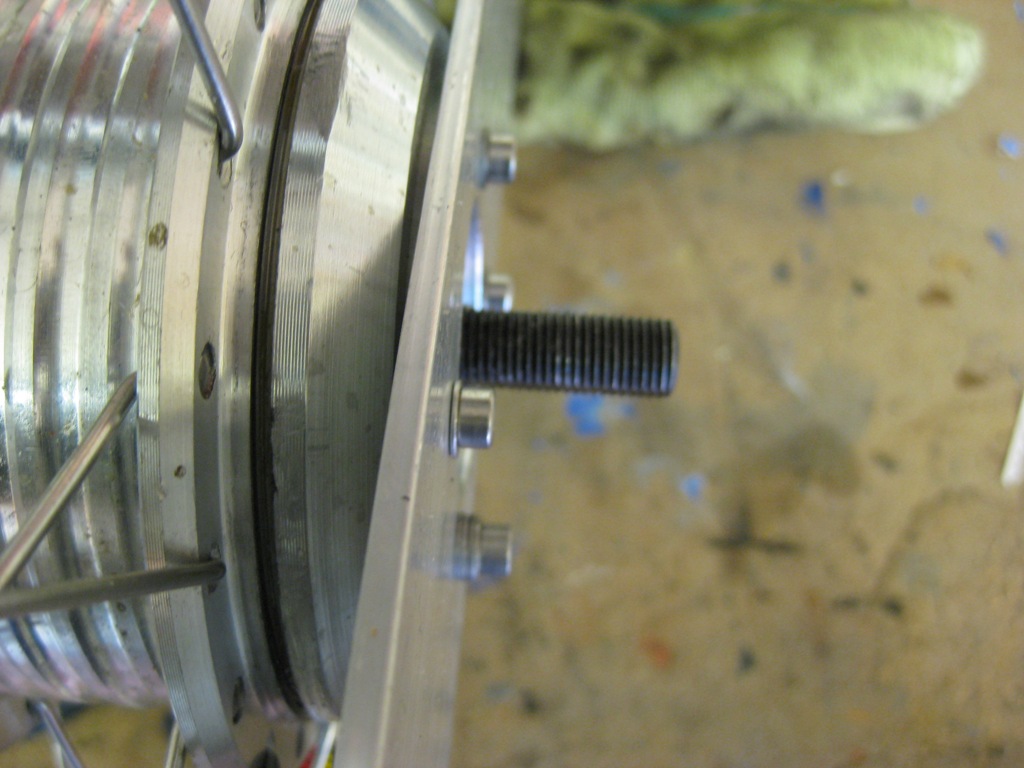

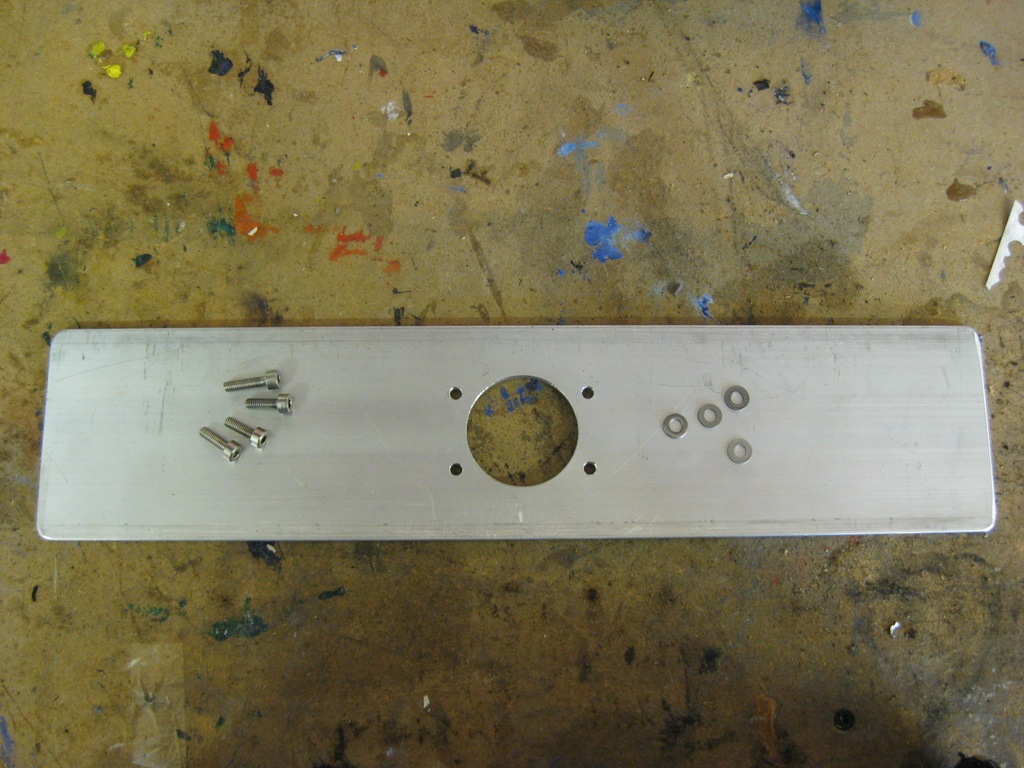

The best place to start is to make a tool to help take the front hub motor plate off as shown below. One of the engineers at work helped me make it up out of a strip of aluminium plate.

The center hole goes over the man shaft and raised boss on the cover plate and then the four holes allow you to screw it down onto the cover plate.

A. Wheel Building - Tongxin in Brompton wheel

B. Building a small A123 Battery Pack

C. E-Brompton First Ride/Tweaks

D. Taking a Tongxin motor apart

You may also like to check out daniel.weck's post here which covers the simlar use of Tongxin & Bafang motors and inpired me to give this a go.

A couple of related links as I was building

Throttle Controls

Connectors

After about three month I had problems with my Tongxin motor and intially stripped it down as shown in this post. I took the motor apart using a vice to clamp the motor plate but this is not really advised as you can easily strip the threads. The other thread also had some pretty blurred pics. I have therefore posted this breakdown as there seems to be very little on the internet about taking these things apart or any decent pictures. I hope it will be of use to some in the future.

I also want to say a big thanks to the member "mkc1" who helped me get to this point.

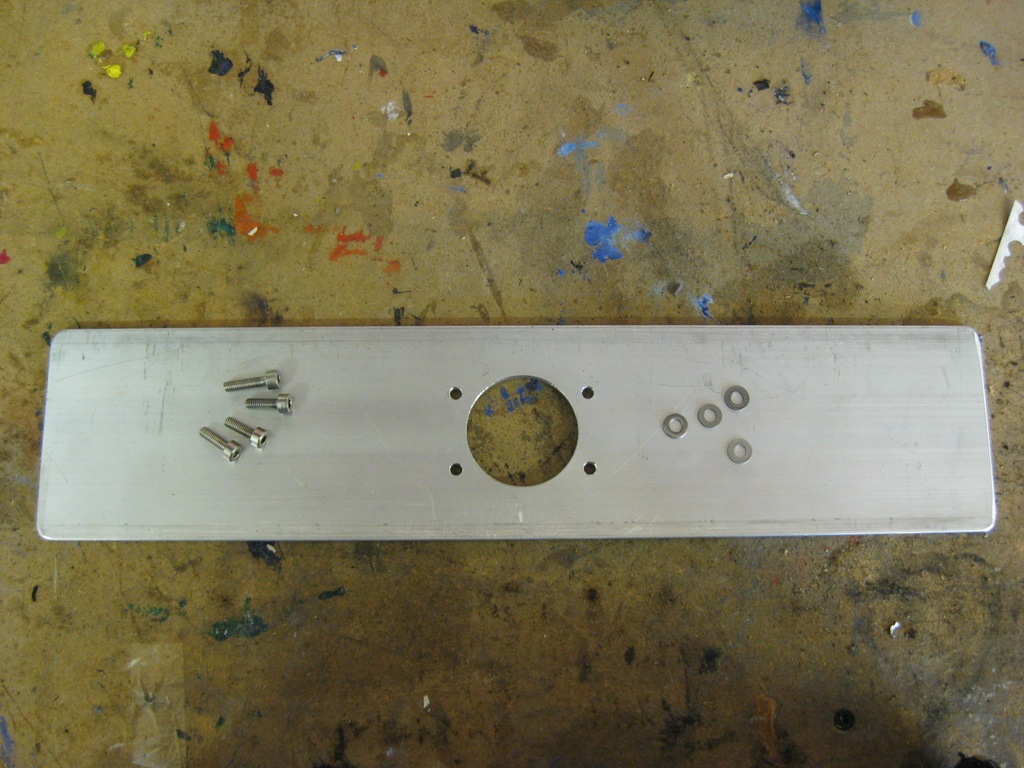

The best place to start is to make a tool to help take the front hub motor plate off as shown below. One of the engineers at work helped me make it up out of a strip of aluminium plate.

The center hole goes over the man shaft and raised boss on the cover plate and then the four holes allow you to screw it down onto the cover plate.

Last edited: