Thanks James,

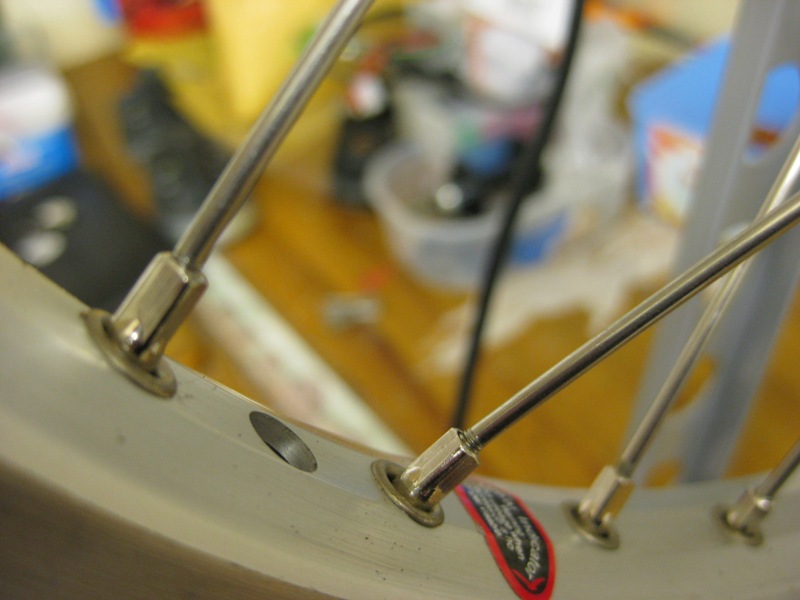

I haven't got to the "squeeze" stress relieving bit yet. I paid for and downloaded Roger Musson's techniques book and followed it to the letter. The mistake I think was that I assumed that his use of the term "freewheel" meant the gear side of the wheel (right side)which is probably why now my trailing spokes are on the outside of the hub flange. Also his example build is based on a rear wheel not a front wheel.

If I had followed the Sheldon Brown's web site page on wheel building I would have got it the right way round. Sadly I see Sheldon died recently but what a great web site and wealth of knowledge he has left for us all.

For my own peace of mind I think I will re-lace it the other way round with the trailing spokes on the inside of the hub flange as you say.

Regards

Jerry

I haven't got to the "squeeze" stress relieving bit yet. I paid for and downloaded Roger Musson's techniques book and followed it to the letter. The mistake I think was that I assumed that his use of the term "freewheel" meant the gear side of the wheel (right side)which is probably why now my trailing spokes are on the outside of the hub flange. Also his example build is based on a rear wheel not a front wheel.

If I had followed the Sheldon Brown's web site page on wheel building I would have got it the right way round. Sadly I see Sheldon died recently but what a great web site and wealth of knowledge he has left for us all.

For my own peace of mind I think I will re-lace it the other way round with the trailing spokes on the inside of the hub flange as you say.

Regards

Jerry

Last edited: