D

Deleted member 4366

Guest

I was given one of those very common 36v behind the seatpost silver fish batteries to have a look at. It wouldn't take a charge, so was effectively dead. I measured the voltage at only 17.8v at the charger socket. No wonder it wouldn't charge.

To strip it down is pretty easy: 4 screws top and 4 screws bottom, and then there's two screws that hold the connector block down at the bottom. Once removed, you can slide the entire contents out of the case leaving the top attached by its wires. You need to get to the balance wires, where they connect to the BMS to measure the individual cell voltages. This will give a good idea what's wrong. The BMS won't allow charging if any cell is below a certain level - probably about 2.5v.

This one was shrink-wrapped, so that had to be cut off, and then it had thin fibreglass panels stuck to each side with double-sided tape, so these had to be prised off to get to the cells. It always looks a bit of a mess, but you can normally put it back fairly easily and use gaffa tape instead of shrink-wrap. This one had a multi-pin connector into the BMS. To measure cell voltages, you start at one end and check between adjacent pairs of holes. Some batteries use the main wires as the last one, so check that the voltage from first to last is the same as the voltage at the main socket. or check between the lowest and the main black and the highest and the main red. for a 36v Li-ion battery, there's normally 10 cells. and 13 for a LiFePO4.

I measured the cell voltages:

0.2, 0.6, 2.7, 1.2, 1.2

1.3, 2.5, 2.5, 2.7, 2.0

Most people would at this stage consider the battery scrap, but all is not yet lost. Most chargers won't do anything with cells that low, but there'es a trick you can use. You need a charged up single spare cell. If you connect it in parallel to a low group by poking wires directly into adjacent holes in the multi-pin connector for just a few seconds, it'll transfer a minimal amount of charge, which is all it takes to get the cell up to about 2.5v; however, it rarely works if the cell is down to zero volts. It worked on these, so I was able to get them all high enough for my lipo charger to take over. Mine can charge up to 6 cells individually.

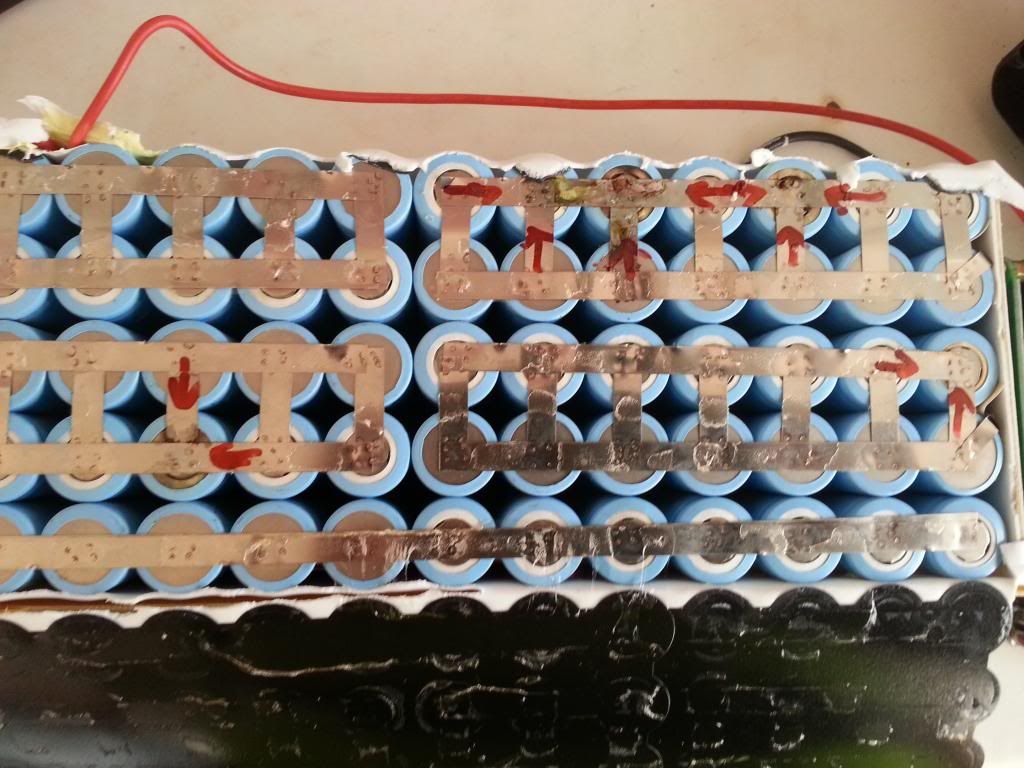

My lipo charger is very versatile. It can charge single cells in groups directly through the balance leads. Here's a photo of the battery innards showing the BMS and the multi-pin connector. I made an adaptor that can charge 6 cells at a time. The single cell is in the foreground:

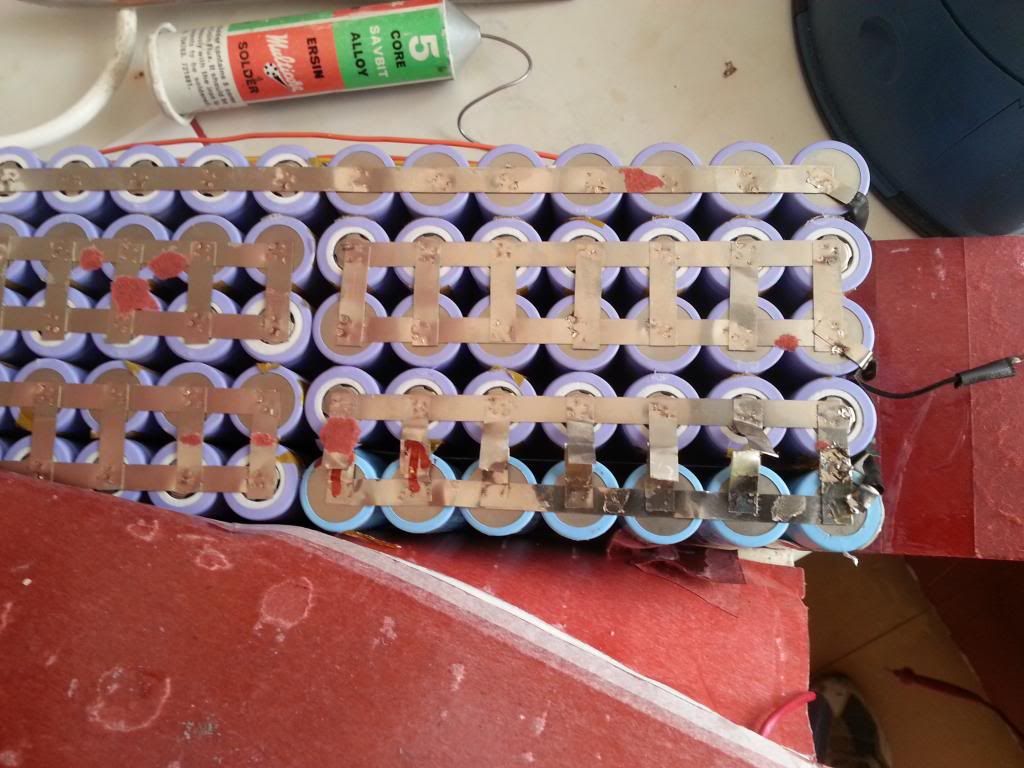

A close-up of the BMS and my adaptor in the multi-pin balance lead connector:

To strip it down is pretty easy: 4 screws top and 4 screws bottom, and then there's two screws that hold the connector block down at the bottom. Once removed, you can slide the entire contents out of the case leaving the top attached by its wires. You need to get to the balance wires, where they connect to the BMS to measure the individual cell voltages. This will give a good idea what's wrong. The BMS won't allow charging if any cell is below a certain level - probably about 2.5v.

This one was shrink-wrapped, so that had to be cut off, and then it had thin fibreglass panels stuck to each side with double-sided tape, so these had to be prised off to get to the cells. It always looks a bit of a mess, but you can normally put it back fairly easily and use gaffa tape instead of shrink-wrap. This one had a multi-pin connector into the BMS. To measure cell voltages, you start at one end and check between adjacent pairs of holes. Some batteries use the main wires as the last one, so check that the voltage from first to last is the same as the voltage at the main socket. or check between the lowest and the main black and the highest and the main red. for a 36v Li-ion battery, there's normally 10 cells. and 13 for a LiFePO4.

I measured the cell voltages:

0.2, 0.6, 2.7, 1.2, 1.2

1.3, 2.5, 2.5, 2.7, 2.0

Most people would at this stage consider the battery scrap, but all is not yet lost. Most chargers won't do anything with cells that low, but there'es a trick you can use. You need a charged up single spare cell. If you connect it in parallel to a low group by poking wires directly into adjacent holes in the multi-pin connector for just a few seconds, it'll transfer a minimal amount of charge, which is all it takes to get the cell up to about 2.5v; however, it rarely works if the cell is down to zero volts. It worked on these, so I was able to get them all high enough for my lipo charger to take over. Mine can charge up to 6 cells individually.

My lipo charger is very versatile. It can charge single cells in groups directly through the balance leads. Here's a photo of the battery innards showing the BMS and the multi-pin connector. I made an adaptor that can charge 6 cells at a time. The single cell is in the foreground:

A close-up of the BMS and my adaptor in the multi-pin balance lead connector: