Tiniest soldering job so far/Adventures in solderspace

- Thread starter guerney

- Start date

I have zillions of phones, and I'm the worst kind of drug dealer - I'm organised and print receipts! Joking. This is a mobile bluetooth thermal printer repair, one I use to print receipts for non-drug transactions, unless the payoff is extremely large and irresistible, and the buyer needs proof of purchase for warranty returns, which I always refuse. Joking again.One of your phones , how many do you have ?

Are you another drug dealer like SW ?

This small stuff would be easy for you deft handed soldering pros. I'm really doing it for the crack, as I have new better printers.

Last edited:

It's vitally important to get paid as fast as possible, print the buyer a receipt andAre you another drug dealer

It's one of these:

I'm phasing them out because their batteries are unobtanium-ion and don't last long, but they're handy for providing receipts on the go.

Last edited:

Well fiddly, as these pins are well.. a fiddly 2mm apart... this is the best I could do, assembled and assembling solderers. It works. I could have another go but I highly doubt I'd want to! Have given the power connector firm waggles side to side, works fine, aint pretty but I'm not either, so that's ok.

In more flattering light:

I used this cheapo soldering iron:

In more flattering light:

I used this cheapo soldering iron:

60W Adjustable Temp Soldering Iron Kit Electronics Welding Solder Irons Tool UK | eBay

Find many great new & used options and get the best deals for 60W Adjustable Temp Soldering Iron Kit Electronics Welding Solder Irons Tool UK at the best online prices at eBay! Free delivery for many products.

www.ebay.co.uk

Last edited:

I have/use the same cheap iron.

If you prime the tip first and feed solder as you go, a nice fluid bed should follow.

If you prime the tip first and feed solder as you go, a nice fluid bed should follow.

I thought it was rubbish initially, but the fault was of course mine - I had used too high a temperature with the large irons, and neglected to tin the tips, clean with wire wool first. For this I used the thinnest needle tip, but had to use a higher temperature. I also used very small amounts of acid-free flux and a desoldering pump. Hell I'm still learning, and thankfully I'm forced to attempt this sort of hashed effort extremely rarely. It was all too damned small! Even when magnified, I could barely see what I was doing. I could rig up a DSLR with a macro lens (and a cover to protect the lens from solder spurts), stream live video to my 42" monitor via HDMI, but this seems to function fine, so I won't. Shaking tiny magnified things, is all I'd see. Lead free solder, instead of my usual toxic Weller.I have/use the same cheap iron.

If you prime the tip first and feed solder as you go, a nice fluid bed should follow.

Last edited:

A neat job my man, a neat job indeedWell fiddly, as these pins are well.. a fiddly 2mm apart... this is the best I could do, assembled and assembling solderers. It works. I could have another go but I highly doubt I'd want to! Have given the power connector firm waggles side to side, works fine, aint pretty but I'm not either, so that's ok.

View attachment 52601

In more flattering light:

View attachment 52603

I used this cheapo soldering iron:

60W Adjustable Temp Soldering Iron Kit Electronics Welding Solder Irons Tool UK | eBay

Find many great new & used options and get the best deals for 60W Adjustable Temp Soldering Iron Kit Electronics Welding Solder Irons Tool UK at the best online prices at eBay! Free delivery for many products.www.ebay.co.uk

Oh I don't know about that! The middle pin is bugging me, but if I attempt this again (I've had to do this three times already, because great globs of solder fused pins together and had to be melted, then removed using the desolderer), it'll unsettle the solder on the other two pins either side - with the repeated attempts at this, heat from the soldering iron has started to unsettle solder on tiny nearby components, so I think I'll have to leave it there... however, the lack of solder on that middle pin is bothering the delicate balance of my mind. I'm not unduly worried about knackering it, because I have loads of those spare cheap printers, therefore may try again. Could be worth it to learn something new.A neat job my man, a neat job indeed

Last edited:

Look at the solder joints in the picture, they all look different, so ask why.In more flattering light:

The only one that looks like it is good, in the one on the left, although even that has a tad to much solder.

The middle joint does not seem to have enough solder.

The right joint looks like it could be a dry joint.

What type of solder did you use ?

Uh oh... and I was so hoping to get a job at your satellite factory soldering Oracs! Yes it's a horrible mess and I'm shocked it works, though this may well be temporary. I spent longest doing and redoing the one on the left.Look at the solder joints in the picture, they all look different, so ask why.

The only one that looks like it is good, in the one on the left, although even that has a tad to much solder.

The middle joint does not seem to have enough solder.

The right joint looks like it could be a dry joint.

What type of solder did you use ?

I used this from my local hardware shop. I'll have another go using proper Weller leaded, open windows for ventilation elc.

Last edited:

This crap tin solder doesn't work without flux, and the leaded Weller is too thick. Now it looks like pins 2 and 3 are joined, but they're not (it's flux plus crudI think), and the printer works fine. I'm more confident this will last, but I'll have to throw it away anyway in favour of the new more robust models I've bought, which print clearer and don't require unobtanium batteries. Good for an adventure in solderspace, but nowt else.

Last edited:

Use flux cored leaded solder.

The lead free stuff is required for manufactured and sold electronics, but you can use leaded on your own stuff.

Lead free solder needs a higher bit temperature and everything needs to be real clean. You can get joints that look like they are dry joints. Best to avoid it.

For cleaning flux off PCBs that blue Polycell brush cleaner applied with an old tootbrush works well. If you have a flux bridge like above, you need to clean it, there could be an almost or partial solder bridge underneath.

The lead free stuff is required for manufactured and sold electronics, but you can use leaded on your own stuff.

Lead free solder needs a higher bit temperature and everything needs to be real clean. You can get joints that look like they are dry joints. Best to avoid it.

For cleaning flux off PCBs that blue Polycell brush cleaner applied with an old tootbrush works well. If you have a flux bridge like above, you need to clean it, there could be an almost or partial solder bridge underneath.

Last edited:

Thank you experts for your advice!

The only soldering adventure this lead-free solder has been good for, is repairing these cheap "Holding hands" (now with magnifier! Amaze your friends!) from Aldi - the arms are held on by collars which are factory tightened around rods, which have a ball joint for swivelment and turnity. With actual use the collar gets loose, and becomes useless for holding anything in position with it's "Hands". Infuriating! I was able to get a high enough temperature to weld the damn things on using this cheap but brilliant 100W Silverline soldering iron (used flux)... and now the holding hands hold securely (flux crud needs nemoving, as does the rust):

The only soldering adventure this lead-free solder has been good for, is repairing these cheap "Holding hands" (now with magnifier! Amaze your friends!) from Aldi - the arms are held on by collars which are factory tightened around rods, which have a ball joint for swivelment and turnity. With actual use the collar gets loose, and becomes useless for holding anything in position with it's "Hands". Infuriating! I was able to get a high enough temperature to weld the damn things on using this cheap but brilliant 100W Silverline soldering iron (used flux)... and now the holding hands hold securely (flux crud needs nemoving, as does the rust):

Silverline 868784 Soldering Iron 100W 100W UK | eBay

Find many great new & used options and get the best deals for Silverline 868784 Soldering Iron 100W 100W UK at the best online prices at eBay! Free delivery for many products.

www.ebay.co.uk

Last edited:

You should not need additional flux, just used cored solder. I dont add additional flux when soldering myself (*see below)I was able to get a high enough temperature to weld the damn things on using this cheap but brilliant 100W Silverline soldering iron (used flux)

Cored solder was invented for a reason so that you dont need to add additional flux and thus make a mess.

Be very cautious with soldering irons in the 25W+ category that do not have temperature control. The bit temperature of say a 100W iron can get very high and the bit will not have that nice shiny ready to solder look.

If the bit is not nicy and shiny it will take longer to do solder joints which increases the heat transfer into other components and plastics start melting.

* One circumstance where using a liquid solvent based flux helps is when soldering fine pitched surface mout components.

Last edited:

That's a much better idea than the tissue paper wrapped around a sharpened matchstick soaked in isopropyl alcohol I was using.For cleaning flux off PCBs that blue Polycell brush cleaner applied with an old tootbrush works well. If you have a flux bridge like above, you need to clean it, there could be an almost or partial solder bridge underneath.

I'll get thiner leaded multicore for future small soldering jobs. Dark surfaces radiate and absorb more heat than shiny.

It's a sledgehammer alright - that cheap 100W Silverline is brilliant for quickly heating larger cables. I've used it to solder controller wires to my battery, all wires for the lights on my bike, and to replace connectors for audio gear. 100W got this 4mm diameter rod hot enough to melt even that rubbish lead-free solder. Flux crud is easily cleaned off using isopropyl. I could file this, make it all smooth neat and tidy, but I don't want to.

I use this method to clean and coat the tip:

Last edited:

Logitech Trackman Marbles are excellent mice, until the switches wear out, which happens after about two years. Can't buy these mice new anymore, and no other mouse will do... therefore my next tiny (not as miniscule as the last) soldering adventure will be to replace the switches on two dead Trackman Marbles.

The Logitech M570 is also excellent, but unlike the Marbles they make my fingers hurt eventually, and their switches are also short lived. Mouse switches don't last long these days, not on Logitechs anyway. There's a new M575 Ergo, I bet it's switches are also crap.

I've ordered thinner toxic leaded flux cored - I'll forget I ordered leaded, because of the lead:

The Logitech M570 is also excellent, but unlike the Marbles they make my fingers hurt eventually, and their switches are also short lived. Mouse switches don't last long these days, not on Logitechs anyway. There's a new M575 Ergo, I bet it's switches are also crap.

Logitech Trackman Doubleclick repair - Replace the switches! [Lots of images]

Logitech Trackman Doubleclick repair - Replace the switches! [Lots of images]

geekhack.org

I've ordered thinner toxic leaded flux cored - I'll forget I ordered leaded, because of the lead:

0.7mm Loctite Multicore Tin Lead 60/40 X39 Solder Wire Electronics 10 Meter! | eBay

Find many great new & used options and get the best deals for 0.7mm Loctite Multicore Tin Lead 60/40 X39 Solder Wire Electronics 10 Meter! at the best online prices at eBay! Free delivery for many products.

www.ebay.co.uk

Last edited:

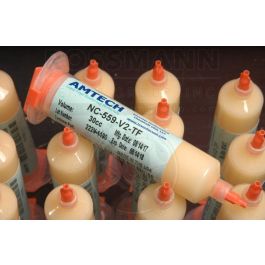

Amtech NC-559-V2-TF Tacky Flux 30CC

<h3>Amtech NC-559-V2-TF is Louis' choice of flux for most logic board repairs. Attn; plungers/needles not currently available, will be back in stock as an option soon! </h3> <p>Flux is what allows solder to flow. If you've created a bridge, need to solder a jumper in a small area, or are...