How do you get at the non-drive bottom bracket bearing?

I can remove the circlip, but the motor housing suggests i need to pull the whole internal motor out to get access.

To replace the non-drive end bearing as suggested will require a virtually complete strip down of the motor. One of the main difficulties is removing the torque sensor, which has an unusual securing nut, this would probably need a special tool. [OK you could use a chisel but would have problems getting it refitted, though a normal nut could be used if it is a standard metric thread]

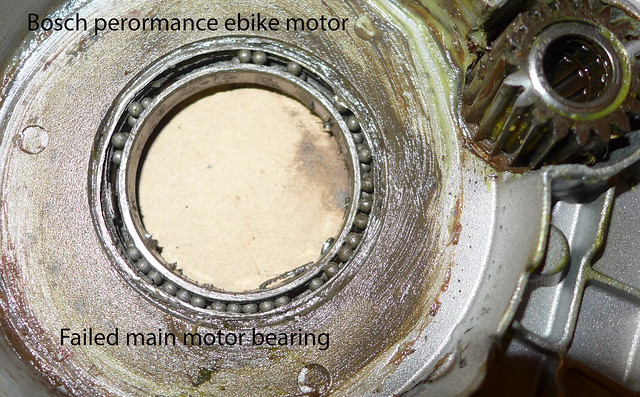

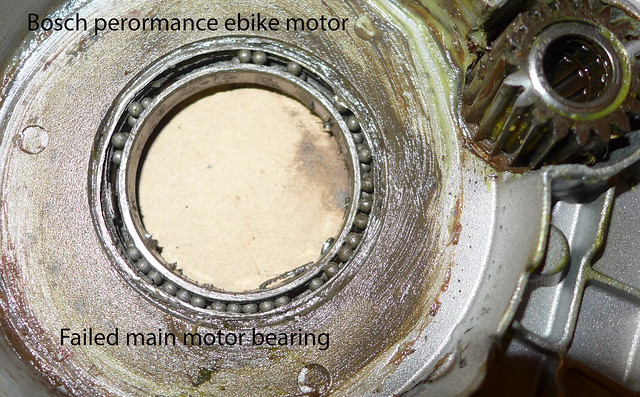

I replaced the main bearing as noted in a previous post, the new bearing only lasted about a year before failing again. The non-drive end bearing had also failed by that time, the motor internals were in a very poor state due to moisture ingress and had no option other than to go down the motor replacement route.

I will post a few photos of what happens to motor internals if there is water ingress, fairly certain ingress was through a failed "O" ring seal on the crankshaft.

[URL='https://flic.kr/p/PXVY83'][URL='https://flic.kr/p/PXVY83'][URL='https://flic.kr/p/PXVY83'][URL='https://flic.kr/p/PXVY83'][URL='https://flic.kr/p/PXVY83'][URL='https://flic.kr/p/PXVY83'][URL='https://flic.kr/p/PXVY83'][URL='https://flic.kr/p/PXVY83'][URL='https://flic.kr/p/PXVY83'][url=https://flic.kr/p/RbSMmA]

Failed motor bearing above, this was the supposedly upgraded type bearing as supplied by ebikeshop. The bearing is a "Max" type bearing and am fairly certain it is not suitable for use in the bosch motor. Max type bearings are primarily intended for static type applications [pivots] The external bearing seal had been fitted, the cynic in me suspects that this external seal is more about pushing the eventual bearing failure out past the warranty period rather than any properly engineered solution. If I was going to do another bearing replacement would probably just use a good quality bearing from SKF.

Motor internals with moisture evident within the casing. There is also some damage evident to the pcb where the shaft fouled it when the main bearing collapsed.

Internal shot of the drawn cup roller clutch internals above. The bearing was full of rusty gunge [photo taken after cleaning attempt] Would have required to use an ultrasonic cleaner to get it cleaned out though the bearing further in may have been problematic. Drawn cup roller clutch bearings are an interference fit and would have required access to a hydraulic bearing press to change, definitely not something that could be pushed out / refitted with the use of a socket.

Drawn cup roller clutch shaft, lots of corrosion and wear marks evident. May have been possible to clean up with some fine emery paper. [Still surprised the motor worked OK up until when the bearing failed, though was giving occasional error codes 500 and 510. If you get these codes would start worrying]

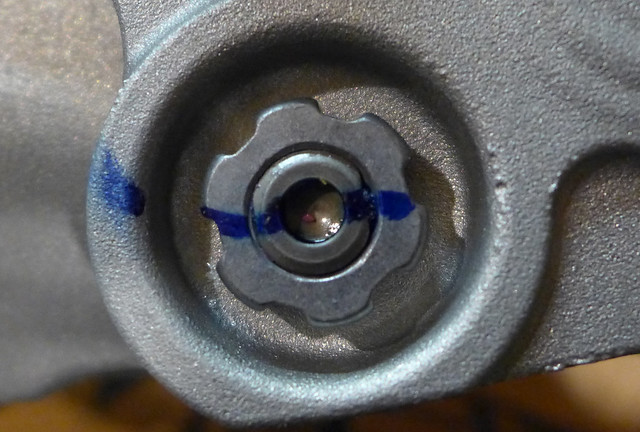

View of the "O" ring seal on the crankshaft. Suspect this "O" ring seal was not effective as there is notable corrosion either side of it. Shaft movement due to the non-drive end bearing failure may not have helped the "O" ring seal performance. Before anyone asks, no I don't use a pressure washer to clean the bike. I do though transport the bike on a tow bar mounted rack and sometimes wonder if that is the reason why I have had so many bearing failures on this bike [3 year old Haibike with ~ 19000km on the clock, every bearing on the bike has been replaced at least once.]

I hope this info is of some use to the bosch powered bike owners out there.

[/URL][/URL][/URL][/URL][/URL][/URL][/URL][/URL][/URL][/URL]