The new Speedict does everything by bluetooth, so you don't need a USB out anymore. The controller has a speed restriction function on it via the white wires. You can join them with a switch to switch on/off the speed restriction, but that doesn't make it legal unless the switch is inaccessible, so a waste of time bothering with it.

If you want to have a go at making one of these remote main switches so that you can just use a small toggle switch, I can send you a PCB, the resistors and capacitor, but you'd have to buy your own FETs. I only have genuine ones that are expensive, but you can buy these counterfeit ones that work OK for the switch:

10 PCS IRFB4110 FB4110 TO-220 POWER MOSFETS Transistor /FREE Registered Mail | eBay

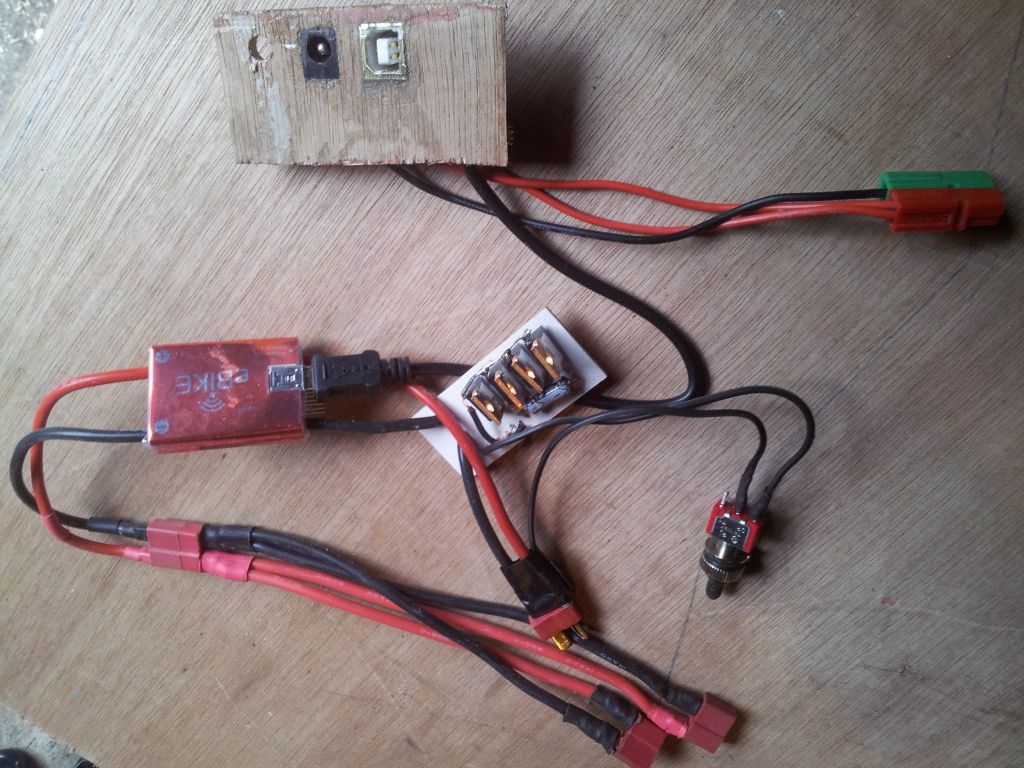

The electronic switch is the whitish thing in the middle, and the battery Deans connector is underneath it. You can see my DC charging jack that connects to the battery charging wires. The little hole to the left is for the toggle switch, which works as the main on/off. The whole panel was glued in underneath the 1.6mm top skin and is covered by a removable panel. The Deans connector underneath the Speedict is for the controller, except that I need that additional two-into-one arrangement because there's two controllrs on this bike.

If you thread the motor wires through brfore fitting the hall sensor connector block, you don't need a big hole. Also, the hole will be in the very bottom, so no water will come in, and if it did, it would fall back out.

You need a hole at the top-front for the throttle and maybe Speedict speed sensor. If you remove the throttle white connector, you can have a small hole, which can be sealed with a bit of silicone afterwards.

) I wanted to double check I have understood how this works. Photos probably the best way rather than oceans of text :

) I wanted to double check I have understood how this works. Photos probably the best way rather than oceans of text :![20130130_234507[1].jpg](/forum/data/attachments/3/3618-0d87cee961c307770ef011ace9770a28.jpg)

![20130130_234414[1].jpg](/forum/data/attachments/3/3617-ccb68a935d37953e30dc6e65a55d5b7e.jpg)

![20130130_234649[1].jpg](/forum/data/attachments/3/3619-012add1c8b0145de0e2b0b9ef0966899.jpg)

![20130130_234737[1].jpg](/forum/data/attachments/3/3620-dd25d1c731b287fca23480a24b57de54.jpg)

![20130130_234507[1].jpg](/forum/data/attachments/3/3618-0d87cee961c307770ef011ace9770a28.jpg)

![20130130_234414[1].jpg](/forum/data/attachments/3/3617-ccb68a935d37953e30dc6e65a55d5b7e.jpg)

![20130130_234649[1].jpg](/forum/data/attachments/3/3619-012add1c8b0145de0e2b0b9ef0966899.jpg)

![20130130_234737[1].jpg](/forum/data/attachments/3/3620-dd25d1c731b287fca23480a24b57de54.jpg)

![20130201_044318[1].jpg](/forum/data/attachments/3/3633-7b1db718d2139626a6f2cc9bd507ea7a.jpg)

![20130201_045739[1].jpg](/forum/data/attachments/3/3634-14f4d96cfcf0536c7dd6c2fb9997eea5.jpg)