Hi, does anyone know where I can find the performance curves for an mxus xf08 hub motor? I would like to see the power output / rotation speed curve and the torque/speed curve. I can't find this information anywhere. Thank you.

Performance curves for mxus motors

- Thread starter Presterjohn

- Start date

I think it is similar but slightly better than the XF07 - my feeling is that it is not quite as good as say a AKM100 or even the much lighter AKM75Hi, does anyone know where I can find the performance curves for an mxus xf08 hub motor? I would like to see the power output / rotation speed curve and the torque/speed curve. I can't find this information anywhere. Thank you.

(I adjusted the wheel sizes to account for different winding speeds)

Performance curves mean nothing. What exactly is it that you want to know in a practical sense?Hi, does anyone know where I can find the performance curves for an mxus xf08 hub motor? I would like to see the power output / rotation speed curve and the torque/speed curve. I can't find this information anywhere. Thank you.

There appears to be two official specs from mxus for that motor and some confusion between the xf07 and xf08 specs. I have the gdr15 (xf15) which is a stronger motor(65nm).Hi, does anyone know where I can find the performance curves for an mxus xf08 hub motor? I would like to see the power output / rotation speed curve and the torque/speed curve. I can't find this information anywhere. Thank you.

There is also an opinion on another forum that to try to understand and take the Chinese specs and their graphs literally have been shown to contribute to early dementia.

Geared Motor

Last edited:

Thanks, those curves are what I am looking for. I want to investigate whether there is any advantage in gearing the output down more.

The XF08C that you can get from PSWPower for £69 is quite fast. While I was trying to sort out the settings for my 22A KT controller, it was reaching 30 mph at 48v. Now that it's set to 15 mph, I can feel that it's not working efficiently. The previous Q128C was much better. It would still reach 27 mph, but the higher internal ratio meant that it worked much better at low speed. At 48v, both those motors would work better in a 20" wheel.Thanks, those curves are what I am looking for. I want to investigate whether there is any advantage in gearing the output down more.

Obviously, both motors would run more efficiently at 36v when restricted to 15 mph, but then you lose 30% of the torque. You could compensate by using a bigger controller -say 28A- but that's a lot bigger in size, so you need to figure out how and where to install it.

When I first got this kit from PSW power [rear wheel, xf08 and all the rest] and fired it up to try it the speed went to 75kph. Once I had set it up to 25kph it must have been going only at 1/3rd of the previous speed. So I was reasoning that if I used one of these as a mid-drive and ran it at higher speed I would get much better hill climbing. I wanted to see the curves to see if when you increase the speed the power just dropped off.

torque varies with the speed. By the way he posts, the OP seems to understand that well, that is why he asked for the charts.Obviously, both motors would run more efficiently at 36v when restricted to 15 mph, but then you lose 30% of the torque.

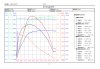

To those who are not initiated to the dark art of motor plots, the top picture is about the XF08 36V 350W. Details are on the right sidebar. The maximum torque point Tmax is at 21.5RPM. On a 26" wheel, that corresponds to 2.6kph. At that speed, the torque is 45.24NM, output is 102W. Torque is good but speed is near stalling which is pretty pointless using the motor that way.

When evaluating a motor for hill climbing ability, look also at Pmax point. For this motor, it's 198rpm or 23.7kph, torque is 18.73NM, output is 385W. The interesting and useable portion is between Tmax and Pmax. Perfect for flatish roads up to 9% - 10% but not for steeper hills. For steeper hills, you need bigger output. Use the motor simulator on ebikes.ca (see Peter Bridge's post above) to work out how much Pmax you need then find a motor that can deliver that amount at the speed you want.

Last edited:

How did you measure 75km/hr. There's no way that the motor was actually going that speed unless you were running with very high voltage. The motor is listed as 270 rpm, which sounds a bit lower than I would have thought. That would be 32km/hr at 36v and in a 26" wheel. My one seemed to go a bit faster than that, so I would have said that it's speed would be closer to 280 rpm at 36v.When I first got this kit from PSW power [rear wheel, xf08 and all the rest] and fired it up to try it the speed went to 75kph. Once I had set it up to 25kph it must have been going only at 1/3rd of the previous speed. So I was reasoning that if I used one of these as a mid-drive and ran it at higher speed I would get much better hill climbing. I wanted to see the curves to see if when you increase the speed the power just dropped off.

If you want to run a 270 rpm motor as a mid-drive, you'd get highest power at around 240 - 250 rpm at 36v or about 320 rpm at 48v. You can calculate your gearing from that.

Both those charts show max rpm as 300 not the listed 270. They may have different windings than the PSWP one. I might test later to find the actual max rpm of mine if I get time.

You normally have to set the number of magnets in the speed sensor and the wheel size to get the correct speed. Which LCD is it?It came up on the display.

That reminds me: If you want to use a hub motor as a crank motor, you must use a controller with current control, not speed control. That means that you're more or less limited to a KT controller unless you want to buy one of those very expensive, waste of money, programmable things.

It's the LCD5. You can set the wheel size anywhere between 6 inches and 28inches so it must be capable of turning at a higher speed. I'm just using the KT controller, I don't know anything about the ones you refer to. I'm just looking at this from an engineering perspective. For example my metal turning lathe has only a 1 h.p. motor but has a gearbox that gives speeds of from 40rpm to 2400rpm. The torque at low speed is sufficient to take 3mm cuts from a steel blank 300mm diameter. So my reasoning is that if you want to climb steep hills then gear the motor down more.

Last edited:

The lathe uses a back gear assembly for the lower speed range giving the higher torqueIt's the LCD5. You can set the wheel size anywhere between 6 inches and 28inches so it must be capable of turning at a higher speed. I'm just using the KT controller, I don't know anything about the ones you refer to. I'm just looking at this from an engineering perspective. For example my metal turning lathe has only a 1 h.p. motor but has a gearbox that gives speeds of from 40rpm to 2400rpm. The torque at low speed is sufficient to take 3mm cuts from a steel blank 300mm diameter. So my reasoning is that if you want to climb steep hills then gear the motor down more.

Your lathe is in no danger when it turns slowly, but you can't do the same with an ebike motor. Riding too slowly is dangerous.It's the LCD5. You can set the wheel size anywhere between 6 inches and 28inches so it must be capable of turning at a higher speed. I'm just using the KT controller, I don't know anything about the ones you refer to. I'm just looking at this from an engineering perspective. For example my metal turning lathe has only a 1 h.p. motor but has a gearbox that gives speeds of from 40rpm to 2400rpm. The torque at low speed is sufficient to take 3mm cuts from a steel blank 300mm diameter. So my reasoning is that if you want to climb steep hills then gear the motor down more.

The minimum safe speed is around 6mph or 9-10kph. In practice, I would recommend 8mph or 12kph as a minimum climbing speed. You can then use the tool at ebikes.ca to lookup how much power you need at that speed for the maximum gradient you want to conquer. That is then your power requirement. Gearing will help but if the motor cannot supply enough power, you'll have to get off the bike and walk up the hill.

How fast a motor spin depends on the kV, which is directly related to the number of turns in the coils. The kV is how many RPM it will spin at for 1V, so it's RPM per volt, which means that it will spin 30% faster at 48v (13S) than at 36v (10S). According to the listing, it's 270 rpm at 36v, which would be a kV of 7.5, but the charts show a max speed of 300 rpm at 36v, which would be 8.33.It's the LCD5. You can set the wheel size anywhere between 6 inches and 28inches so it must be capable of turning at a higher speed. I'm just using the KT controller, I don't know anything about the ones you refer to. I'm just looking at this from an engineering perspective. For example my metal turning lathe has only a 1 h.p. motor but has a gearbox that gives speeds of from 40rpm to 2400rpm. The torque at low speed is sufficient to take 3mm cuts from a steel blank 300mm diameter. So my reasoning is that if you want to climb steep hills then gear the motor down more.

Motors make their maximum power and efficiency at approximately 75% to 80% of their maximum speed. For a crank-drive, the ideal is to have that speed a bit higher than your natural pedal speed. Most people have a natural and comfortable pedal speed of between 60 and 100 rpm. Only you know what yours is.

First, you need to find out what the kV is for your paticular motor by measuring its max RPM and your battery voltage at that time, then you can decide which voltage you want to run at, then you can calculate its speed for max power and efficiency, then you can calculate the gearing between the motor and the crank you need to get the crank-speed correct for you.

You cannot gear down a crank-motor to get more climbing torque because it's driving the cranks, not the bike. It's the wheel that you have to gear down.

If you want serious climbing torque from a hub-motor, one way is to mount it on a jack-shaft between the cranks and the wheel. That works really well on a trike because you can take the final drive from a sprocket fixed to the disc mounting, and drive the axle sprocket with a simple chain, but on a bicycle, the final drive would be on the wrong side, so you'd have to use a left-hand freewheel on the left side of the bike for the final drive from the jackshaft.

All things considered, I think a normal crank motor, like a TSDZ8 might have been better than a hub-motor because you can configure it for whatever torque you want by changing the chainwheel size.

Last edited:

Related Articles

-

MTF Enterprises announces acquisition of EMU Electric Bikes

MTF Enterprises announces acquisition of EMU Electric Bikes- Started by: Pedelecs

-

Wisper 806T folding bike wins Which? ‘Best Buy’

Wisper 806T folding bike wins Which? ‘Best Buy’- Started by: Pedelecs

-

Sustrans calls for protected cycle lanes

Sustrans calls for protected cycle lanes- Started by: Pedelecs

-

Amazon launch their first UK e-cargo micromobility hub

Amazon launch their first UK e-cargo micromobility hub- Started by: Pedelecs