Got a wee issue on my 1000Lm light...

The sheath on the cable which exits the light housing running to the connector has come away from the housing quite considerably. A roadside repair to the quick-release bracket I hadn't screwed in properly in very poor light is likely the culprit o).

o).

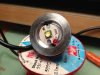

Light cut out and I initially tried to wrap the wires in tape to get it working (I am assuming black and red wires should not touch(?!!) ) .. and it worked for a day before my having to fiddle again. Photo here :

![20130116_012412[1].jpg](/forum/data/attachments/3/3517-8e1c5773a9a7dc11d495b37e6730f4c6.jpg)

Am I right in assuming that i need to insulate the copper wires which have become exposed from the protective sheaths and that these should not touch each other (light didn't work when they did) ? Is there anything neat I can do to make more weatherproof and long-term fix than wrapping the black and red wires again and hoping for the best ?

I've taken the lens and casing off to expose the light filament, but the wiring is behind this within a robust unit and not sure whether I should / can pull it out to get at the wiring exiting the light so as to cut and refix after stripping back the main thick outer black cable sheath to expose intact red / black wires (if that makes any sense ... )

)

The sheath on the cable which exits the light housing running to the connector has come away from the housing quite considerably. A roadside repair to the quick-release bracket I hadn't screwed in properly in very poor light is likely the culprit

Light cut out and I initially tried to wrap the wires in tape to get it working (I am assuming black and red wires should not touch(?!!) ) .. and it worked for a day before my having to fiddle again. Photo here :

![20130116_012412[1].jpg](/forum/data/attachments/3/3517-8e1c5773a9a7dc11d495b37e6730f4c6.jpg)

Am I right in assuming that i need to insulate the copper wires which have become exposed from the protective sheaths and that these should not touch each other (light didn't work when they did) ? Is there anything neat I can do to make more weatherproof and long-term fix than wrapping the black and red wires again and hoping for the best ?

I've taken the lens and casing off to expose the light filament, but the wiring is behind this within a robust unit and not sure whether I should / can pull it out to get at the wiring exiting the light so as to cut and refix after stripping back the main thick outer black cable sheath to expose intact red / black wires (if that makes any sense ...

Last edited:

![20130116_143853[1].jpg](/forum/data/attachments/3/3525-894c2a78843f579f3414a62947e3d6a4.jpg)