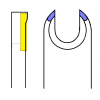

Nothing seems straightforward with this conversion. I'm trying to convert a 1990s Giant Cypress SE using a Cyclotricity front wheel kit. I've already had to hack some metal off one of the cranks to get the PAS rotor to fit and remove the disk brake securing screws and spacer from the hub. I thought I was on the last lap until I tried to fit the wheel! (I'd already ensured it would fit into the dropouts and worked out I needed to add an M12 washer behind the each torque washer to ensure the hub cleared the forks). It wasn't until I tried fitting the (flanged) axle nuts that I realised I'd missed something. My forks have QR dropouts with a recess to retain the skewer should it slacken slightly; and the flanges of the axle nuts are too large to fit those recesses. Specifically, the recesses are 21mm dia and the flanges on the axle nuts are 25mm dia. I've attached photos.

I thought of fitting M12 washers on the outboard side of the dropouts, but the standard form A and form B washers are 24mm OD, so won't fit, and I haven't managed to source M12 flat washers with 21mm OD. Another approach might be to turn down the axle nut flanges to 21mm dia to fit the dropouts; but is that safe? Perhaps flanged M12 x 1.25 (i.e. fine) nuts with 21mm flanges might exist?

All help gratefully received. Thanks for looking, Geoff

I thought of fitting M12 washers on the outboard side of the dropouts, but the standard form A and form B washers are 24mm OD, so won't fit, and I haven't managed to source M12 flat washers with 21mm OD. Another approach might be to turn down the axle nut flanges to 21mm dia to fit the dropouts; but is that safe? Perhaps flanged M12 x 1.25 (i.e. fine) nuts with 21mm flanges might exist?

All help gratefully received. Thanks for looking, Geoff