Hi

I want to build an ebike using a Tern Link P9 2014. This has a 20" 9 speed derailleur setup. I want to keep the weight as light as possible, so a mid-drive kit isn't the way to go. Besides, I won't be tackling huge hills.

Because the forks are aluminium, I want to mount the motor in the rear hub. I'll use a pair of torque arms to be safe.

I know that 250w is the EU limit, but I'd possibly go to 350w but no more as I don't want to go mad.

I'd really like a proper torque sensing controller. I tried a Peugeot AE 21 recently and it rode beautifully because of a properly sorted torque sensor. I'd like to recreate that experience as closely as possible.

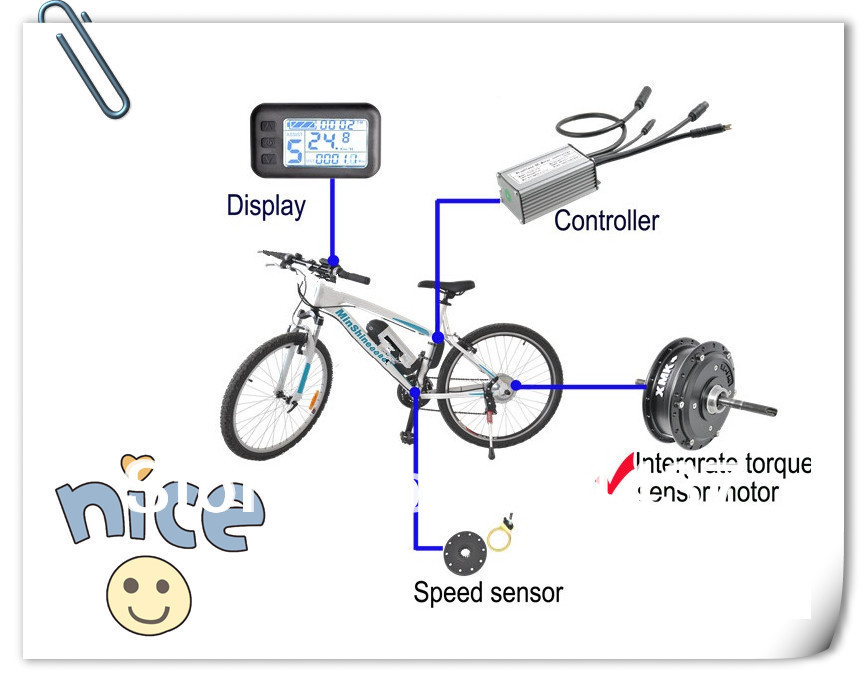

I know the Bionx kit would give me everything I need but it's pretty expensive. At the other end of the scale, I came across this:

http://www.aliexpress.com/item/XMK-Electrical-Bike-System-Kit-Meter-Controller-Motor-Torque-sensor-Speed-Sensor/593238722.html?tracelog=back_to_detail_b

This appears to do everything I want but is it any good? It would also mean building a wheel around the motor - how much roughly would that add to the cost?

Is there some other kit I should be looking at or am I mad to be trying for a torque sensored solution. Cadence sensored kits are much more readily available and I'm wondering how they ride. I've heard they're not great at hill starts for example.

Any ideas gratefully received.

I want to build an ebike using a Tern Link P9 2014. This has a 20" 9 speed derailleur setup. I want to keep the weight as light as possible, so a mid-drive kit isn't the way to go. Besides, I won't be tackling huge hills.

Because the forks are aluminium, I want to mount the motor in the rear hub. I'll use a pair of torque arms to be safe.

I know that 250w is the EU limit, but I'd possibly go to 350w but no more as I don't want to go mad.

I'd really like a proper torque sensing controller. I tried a Peugeot AE 21 recently and it rode beautifully because of a properly sorted torque sensor. I'd like to recreate that experience as closely as possible.

I know the Bionx kit would give me everything I need but it's pretty expensive. At the other end of the scale, I came across this:

http://www.aliexpress.com/item/XMK-Electrical-Bike-System-Kit-Meter-Controller-Motor-Torque-sensor-Speed-Sensor/593238722.html?tracelog=back_to_detail_b

This appears to do everything I want but is it any good? It would also mean building a wheel around the motor - how much roughly would that add to the cost?

Is there some other kit I should be looking at or am I mad to be trying for a torque sensored solution. Cadence sensored kits are much more readily available and I'm wondering how they ride. I've heard they're not great at hill starts for example.

Any ideas gratefully received.