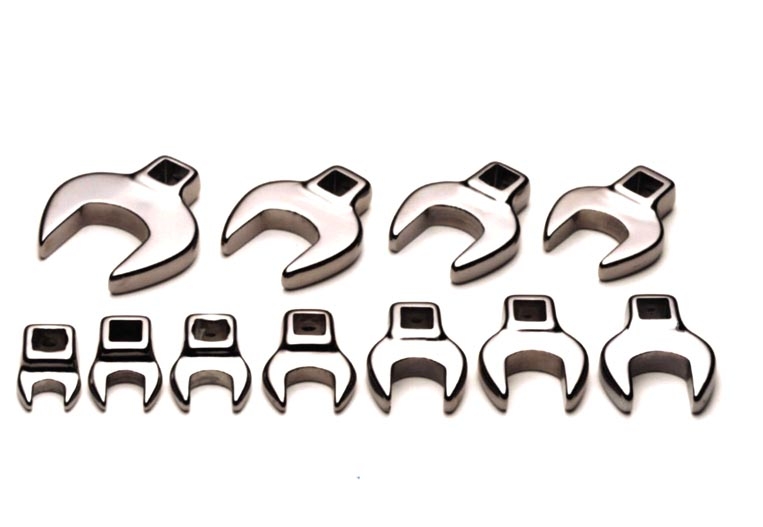

Yes Jerry, that type of thing. Mine does not look quite as posh as that , I found it on a rubbish tip about 30 years ago. Having thought about it, you could probably use a long ring spanner , and tighten it by pushing it with the bathroom scales. Getting in the right position to read the numbers might involve the skills of a contortionist though.

Apparently, Torque settings are dependent on a number of factors in addition to bolt diameter and thread pitch. The recommended setting is typically 65% of the failure force. It also depends if the thread is dry, lubricated with oil, or with anti seize compound. Then there are materials to consider, mild steel, high tensile steel, or various alloys. Bear in mind that the axle end where the cable enters is already well below its original strength as a result of being drilled to take the cable. To be honest, 35 Newton metres seems excessive to me.

Tightening bolts by feel is a thing we learn by experience. If it falls off it was too loose, if it shears off it was too tight. As we progressively tighten a nut , progressively more effort is required with each turn or part turn. We subconsciously feel the point where the amount of effort required stops increasing and reaches a plateau. At that stage we are in danger of exceeding the material`s modulus of elasticity.

As a kid, I asked my dad how far to tighten a nut. His reply has stayed with me all my life. His advice was "Tight, but not silly tight". Words of wisdom indeed.

Remember when using the fish scales method that torque is quoted in Newton Metres which is the same as Kilogram Metres. So extend the spanner to 1 metre long by taping it to a bit of wood , unless you are smart enough to allow for the spanner length in your calculations.