I have just acquired a Kalkhoff Pro Connecct Allround, without battery, from a local place that gives work to people with learning disabilities.

it was beyond what they knew what to do with so I took it away and gave them half a dozen other bikes i had been looking to get rid of.

Can anyone give me any info on these bikes as all the ones on the manufacturers site now seem to have model number liekm C 9-G or similar.

I am not familiar with this type of drive system.,.believe I read somewhere that is Panasonic.

It has a Shimano 8 speed internal Nexus rear hub and rim V-brakes.

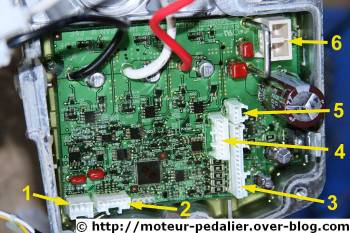

I fed it 24 volts and the display showed the lowest voltage on the power indicator. 42 volt also gave the same low voltage indication. ???Odd. surely it is nto greater than 40 volt battery pack. so i am guessing either a fault or that third wire is playing a part in the display indication. (see pic below)

Assist does work, though the mode button although it does click does not change the mode level..it is stuck in the middle power setting.

Lights did work, but changing the rear bulb that was not working resulted in a short 'crack' from around the crank area, and then the front light went out..guessing a fuse..but can not see one. Before the lighting stopped working it was giving out 1.5 volts

Any one tell me what the correct voltage should be for the battery pack and what that third grey wire does.

Also any other info you can supply greatly appreciated.

Wiring schematic? motor type..brushed I am guessing?

it was beyond what they knew what to do with so I took it away and gave them half a dozen other bikes i had been looking to get rid of.

Can anyone give me any info on these bikes as all the ones on the manufacturers site now seem to have model number liekm C 9-G or similar.

I am not familiar with this type of drive system.,.believe I read somewhere that is Panasonic.

It has a Shimano 8 speed internal Nexus rear hub and rim V-brakes.

I fed it 24 volts and the display showed the lowest voltage on the power indicator. 42 volt also gave the same low voltage indication. ???Odd. surely it is nto greater than 40 volt battery pack. so i am guessing either a fault or that third wire is playing a part in the display indication. (see pic below)

Assist does work, though the mode button although it does click does not change the mode level..it is stuck in the middle power setting.

Lights did work, but changing the rear bulb that was not working resulted in a short 'crack' from around the crank area, and then the front light went out..guessing a fuse..but can not see one. Before the lighting stopped working it was giving out 1.5 volts

Any one tell me what the correct voltage should be for the battery pack and what that third grey wire does.

Also any other info you can supply greatly appreciated.

Wiring schematic? motor type..brushed I am guessing?

Last edited: